You should check the charger even if you own the best cordless drill sets. So, How To Test A Cordless Drill Battery Charger?

The battery charger is an essential component of a cordless drill. Keeping the drill’s battery charged and ready to use is crucial. Regular testing of the battery charger ensures it functions correctly and gives the drill battery the correct amount of power.

It not only helps prolong the battery’s life but also helps ensure that the drill operates efficiently. This outline will guide you through testing a cordless drill battery charger and ensuring its proper functioning.

Purpose of Testing a Cordless Drill Battery Charger

The purpose of testing a cordless drill battery charger is to determine whether it is functioning correctly and providing the appropriate amount of power to the cordless drill battery. Testing the battery charger helps ensure that it delivers the correct voltage and current, which is essential for the proper functioning of the drill.

A battery charger that is not functioning correctly can cause damage to the battery or even the drill, resulting in a decrease in performance or complete failure. Testing the battery charger helps to identify any issues and address them before they cause further damage. It also helps to ensure the battery is charged correctly and efficiently, prolonging its life and reducing the need for frequent replacements.

Required Instruments to Test the Charger of a Cordless Drill

To test the charger of a cordless drill, you will need the following instruments:

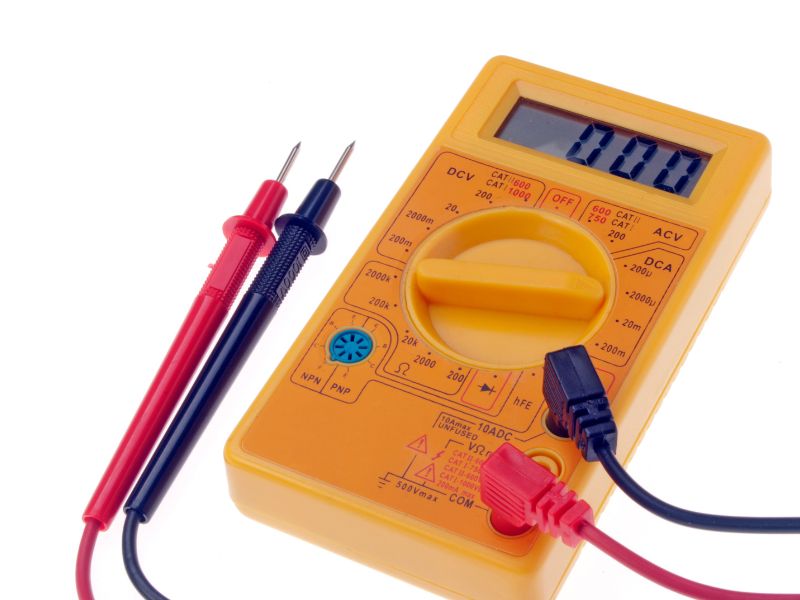

- Multimeter: A multimeter is an electronic testing device that measures electrical properties, such as voltage, current, and resistance. A multimeter for measuring electrical currents and voltages is necessary to test a cordless drill battery charger.

- Screwdriver: You will need a screwdriver to open up the charger enclosure to access the electrical components.

- Continuity Tester: A continuity tester is a simple device that can determine if there is an electrical connection between two points. It can help test the connections within the battery charger.

- Protective gear: When working with electrical components, wearing gloves and safety glasses is essential to protect your hands and eyes from any potential hazards.

How To Test A Cordless Drill Battery Charger – Steps

Before beginning the testing procedure, ensure the charger is unplugged from the power source and unclipped from the battery pack.

Before starting the testing procedure, it is vital to ensure the battery charger is unplugged from the power source and unclipped from the battery pack. It is a crucial safety measure that helps to prevent electrical shock and other hazards. Additionally, wear insulated gloves and safety glasses to protect yourself from electrical shock and other hazards during the testing process.

Open up the charger enclosure using a screwdriver.

In some cases, it may be essential to open the charger enclosure to access the charging terminals for testing. It is typically only done if there is a need to inspect the charger’s internal components or if the charging terminals are not readily accessible.

Here are the steps to open the charger enclosure:

- Locate the screws that hold the charger enclosure together.

- Use a screwdriver and remove the screws, and set them aside.

- Carefully separate the two halves of the enclosure and remove the top half to access the internal components.

It is essential to be cautious while opening the charger enclosure, as the internal components may be sensitive and can be easily damaged. Additionally, keep track of all the screws and parts so they can be reassembled correctly.

Visually inspect connections and wiring.

Inspecting the connections and wiring can help identify any obvious issues with the battery charger. Here are the steps to examine the connections and wiring:

- Locate the connections and wiring within the charger enclosure.

- Carefully inspect each connection to ensure it is secure and free of corrosion.

- Look for any damaged or frayed wires and ensure they are not touching any metal components or other electrical parts.

Inspect the wiring for any signs of melting or burning, which can indicate a problem with the charger.

If any issues are found during the inspection process, it is best to have the battery charger repaired by a professional. Attempting to fix it yourself can result in further damage or even a safety hazard.

Test each connection with a multimeter/continuity tester according to the manufacturer’s instructions.

Test each connection with a multimeter/continuity tester according to the manufacturer’s instructions. Doing so will help ensure that each connection is secure and will not result in any flickering or other problems once you turn the power back on. If you need help determining whether your cordless drill battery charger is functional, it’s crucial to test it with a multimeter or continuity tester. It will help you determine whether the charger uses the correct amount of power and check for any shorts or other issues.

To test your charger with a multimeter. First, make sure that the multimeter is set to the correct setting. Most chargers use AC current, so you’ll want to put your multimeter to AC voltage. Once the multimeter is appropriately set, touch the red lead to the positive terminal on the charger and the black lead to the negative terminal.

You should see a reading on the multimeter display if everything is working correctly. The accurate reading will depend on the type of charger you’re using, but it should be within the range specified by the manufacturer. If you don’t see a reading or if the reading is outside of the specified range, your charger may have an issue.

You can also use a continuity tester to test your charger. To do this, touch one lead of the continuity tester to the positive terminal on the charger and the other to the negative terminal. If there is continuity between these two points, then that means that your charger is functional. However, if there is continuity between these points, your charger may be fine.

How To Test A Cordless Drill Battery Charger- Measuring the Results

Steps to measure the voltage output of the charger

Measuring the voltage output of the battery charger is an essential step in testing its functionality. Here are the steps to measure the voltage output:

- Set the multimeter to measure voltage.

- Connect the multimeter’s probes to the charging terminals of the battery charger.

- Plug in the charger to a power source and turn it on.

- Please wait a few minutes for the charger’s maximum voltage output.

- Read the voltage reading on the multimeter.

- Compare the voltage reading with the specifications listed by the manufacturer for the battery charger.

It is vital to ensure that the voltage reading is within the specified range provided by the manufacturer. A voltage reading that is too high or too low can indicate an issue with the charger and should be addressed by a professional.

Additionally, it is essential to note that some battery chargers may have multiple voltage outputs depending on the charging stage, so follow the manufacturer’s instructions when testing the voltage output.

Testing the Charger’s Current Output

Measuring the current output of a battery charger can help determine if it is functioning correctly and provide the correct amount of charging current to the battery pack.

Here are the steps to test the current output of a battery charger:

- Set the multimeter to measure current (amperage).

- Connect the multimeter in series with the battery charger and the battery pack by placing the multimeter probes in between the charger and the battery pack.

- Plug in the battery charger to a power source and turn it on.

- Please wait a few minutes for the charger to reach its maximum current output.

- Read the current reading on the multimeter.

- Compare the current reading with the specifications listed by the manufacturer for the battery charger.

It is vital to ensure that the current reading is within the specified range provided by the manufacturer. A current reading that is too high or too low can indicate an issue with the charger and should be addressed by a professional.

Additionally, it is essential to note that some battery chargers may have multiple current outputs depending on the charging stage, so be sure to follow the manufacturer’s instructions when testing the current output.

Explanation of how to interpret the results of the tests conducted

Interpreting the results of the tests conducted on a cordless drill battery charger is crucial in determining if it is functioning correctly.

Here is how to interpret the results of the tests:

Visual Inspection: If any apparent issues, such as damaged connections or frayed wires, were found during the visual inspection, the battery charger likely needs to be repaired or replaced.

Connection Testing: If any connections within the battery charger show an open circuit or a broken connection during the continuity testing, the charger likely needs to be repaired or replaced.

Voltage Output Testing: If the voltage reading on the multimeter is within the range specified by the manufacturer, the battery charger is likely functioning properly. However, if the voltage reading is too high or too low, it could indicate an issue with the charger, which should be addressed by a professional.

Current Output Testing: If the current reading on the multimeter is within the range specified by the manufacturer, the battery charger is likely functioning correctly and providing the correct amount of current to the battery pack. However, if the current reading is too high or too low, it could indicate an issue with the charger, which should be addressed by a professional.

It is important to note that the tests conducted on a battery charger should only be used as a guide and that professional assistance may be needed to determine the actual cause of any issues with the charger.

How To Test A Cordless Drill Battery Charger – Safety Precautions

Safety is essential when testing a cordless drill battery charger, as there is potential for electrical shock and other hazards. Here are some safety measures to be taken before starting the testing process:

- Unplug the charger from the power source: Always ensure the charger is unplugged from the power source before beginning the testing process. It will prevent the risk of electrical shock.

- Wear protective gear: Wear gloves and safety glasses to protect your hands and eyes from potential hazards.

- Use caution when working with electrical components: Be mindful of the electrical components within the battery charger, as they may be hot or carry an electrical charge.

- Use a multimeter designed for the purpose: Make sure to use a multimeter designed for measuring electrical currents and voltages. A multimeter not intended for this purpose may not give accurate readings or could be damaged during the testing process.

- Follow manufacturer’s instructions: Always follow the manufacturer’s instructions and guidelines when testing the battery charger, as different models may have other requirements.

FAQs

Why do I need to test my battery charger?

Testing your battery charger can help determine if it is functioning correctly and provide the correct amount of charging current to the battery pack. It can extend the life of your battery pack and ensure that your cordless drill is always ready to use.

Can I test my battery charger myself?

Yes, you can test your battery charger using a multimeter and follow the manufacturer’s instructions. However, seek professional assistance if you are not confident in your electrical knowledge or experience.

What kind of multimeter do I need to test my battery charger?

You will need a multimeter designed for measuring electrical currents and voltages. Ensure to follow the manufacturer’s instructions for your specific battery charger model.

What if the results of my tests indicate an issue with my battery charger?

If the results of your tests indicate an issue with your battery charger, it is best to seek professional assistance. Attempting to repair the charger yourself may be dangerous and cause further damage.

How often should I test my battery charger?

It is recommended to test your battery charger once every six months to a year or as needed if you suspect an issue with the charger.

Is testing a battery charger dangerous?

Testing a battery charger can be dangerous if proper safety measures are not taken. Always make sure to unplug the charger from the power source and wear protective gear, such as gloves and safety glasses. If you need more confidence in your electrical knowledge or experience, it is best to seek professional assistance.

Conclusion

Testing a cordless drill battery charger is a straightforward process that can be done with just a few simple tools. To test the charger, you must first check for proper voltage and amperage output using a multimeter. Then, you can test the charging process by inserting a battery and observing if it charges fully and promptly. If the charger isn’t working correctly, it may be due to a faulty power outlet, damaged cable or wiring, or a malfunctioning charger unit. In such cases, it’s best to consult the manufacturer’s instructions or seek professional help to ensure proper testing and repairs. By following these steps, you can ensure that your cordless drill battery charger is functioning optimally and ready to power your drill.